Variable rate technology (VRT) is a new and powerful advancement in the precision agriculture revolution. VRT reduces input and labor costs while maintaining whole-farm profitability and increasing the sustainability of a grower’s farming practices.

So, what do farmers and growers need to know to implement VRT into their operations successfully?

Table of Contents

What is Variable Rate Technology?

VRT uses data and automation to apply fertilizer, crop protection products, seeds and even irrigation water at different rates in different locations without a grower having to change application rates or make multiple passes manually.

Variable rate technology in precision agriculture focuses on many areas of crop production, including applying herbicides and pesticides, lime, gypsum and other common crop nutrients, seeding and detecting weeds and diseased crops.

VRT works by using GPS and GIS technology to locate precise locations in the field for material application, combined with collected data that informs a VRT-enabled piece of equipment, such as a seeder, sprayer or fertilizer spreader, exactly where and at what rates to apply products.

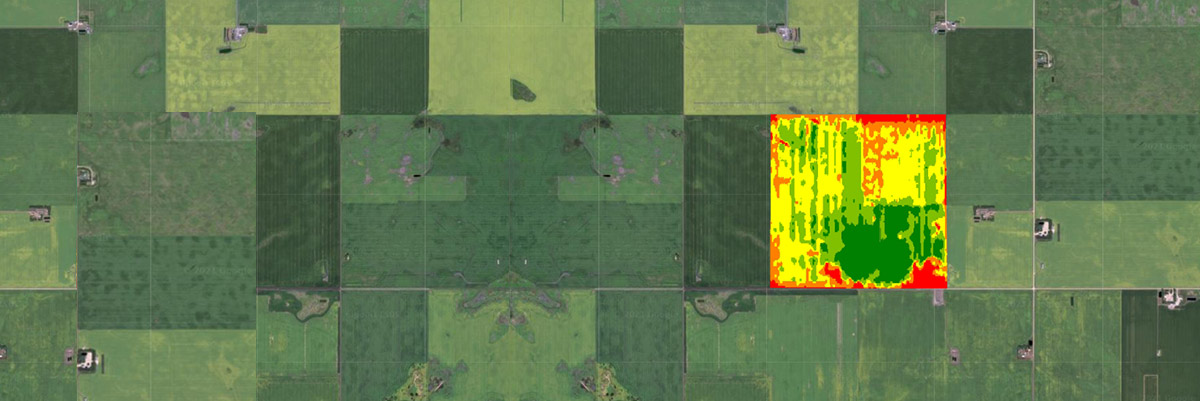

The first step in VRT is to create farmer-developed management zones. These zones are typically mapped through the uniformity of their characteristics as determined by soil testing, yield monitoring results and other data such as remote sensing imagery. A standard management zone in a VRT system would map high, medium and low productivity areas within a field.

VRA Technology

Types of Variable Rate Application Systems

VRT is based on variable rate application (VRA), which means applying materials in such a manner that the application rate is varied based on precise locations. VRA works by using either a map or a sensor-based system.

- Map-Based VRA

The application follows a map, typically called a prescription map, based on GPS coordinates. In a map-based VRA system an agronomist creates the prescription map, commonly referred to as a ‘script,’ and it is uploaded into the farmer’s data system. This prescription map then informs a VRT-enabled piece of equipment, such as a seeder, sprayer or spreader, of the application rates based upon location.

- Sensor-Based VRA

Application is determined based on sensors that inform the VRT-enabled system where and at what rates to apply materials. Sensor-based VRA is typically real-time, allowing a grower to react to precise conditions at the time of application. Sensor-based VRA is most commonly used in irrigation applications, such as center pivot irrigation systems with VRT capabilities.

How Does VRT Increase Farm Profitability?

According to the United States Department of Agriculture (USDA), U.S. corn farmers that used VRT combined with yield mapping had the highest cost savings ($25 per acre) compared to other precision agriculture technologies such as guidance systems and soil mapping.

VRT increases farm profitability by minimizing and maximizing the rate of crop inputs applied (such as fertilizer, weed control, seeds and water) based on predictive analysis of where those inputs will result in the most profitability. VRT, in essence, limits the effect of variability within crop production, producing an overall more profitable yield with less inputs needed.

What Can Be Applied Through Variable Rate Application Technology in Agriculture

Any input a farmer or grower applies to their crop through the production cycle can, in theory, be applied using a variable rate application or via variable rate technology.

Variable Rate Fertilizers

The first advance in variable rate technology (VRT) to take farmers and growers by storm was the use of variable rate fertilizers (VRF) in the early 1990s.

VRF systems allow growers to vary the amount of fertilizer applied through a field, responding to specific soil conditions and crop needs. Like most VRT technology, variable rate fertilizers are most used amongst soybeans and corn row crop farmers. Approximately 60% of U.S. corn and soybean farmers had adopted variable rate fertilization technology as of 2016.

While variable-rate fertilizers are most commonly used with nitrogen fertilizer applications, the same technology can be used with other macronutrients crucial to crop growth, such as phosphorous or potassium applications. Also, variable rate fertilization can be made using spreaders for granular products or sprayers for liquid products.

Variable Rate Seeding

Variable rate seeding (VRS) became popular in the early 2000s.

Planters and seeding drills can be transformed into VRA sensors by attaching a motor or gearbox that varies the rate of seed applied as the farmer drives through the field. This allows growers to break away from traditional flat rate seeding techniques. Instead, they can lay down more or less seed based upon the results of soil testing and yield maps, matching plant populations to higher productivity zones within a field.

For instance, a portion of a field with high-class soils amenable to high-yielding crop production can support a higher plant density. On the other hand, regions identified as having poor fertility will be more profitable if they are seeded less densely because the crop will have less competition for growth. Plus, the farmer saves money by planting fewer seeds.

Variable Rate Weed Control

Weeds can be more precisely controlled using variable rate applications of herbicides. This saves farmers money by reducing the overall amount of herbicides applied and improving yield outcomes by giving crops the best chance to compete for water and nutrients without weed pressure.

In a pre-emergent application, a map-based VRT system is used based on historical data on weed infestation in the field by management zone. Post-emergent variable weed control is enabled with real-time, remote sensing data, such as satellite or drone imagery, that can identify areas of weed pressure as occurring throughout the season.

VRA Technology

Variable Rate Irrigation

Variable rate irrigation is the most recent development in VRT.

In a variable rate irrigation system, irrigation infrastructure is enabled with automation capabilities and then informed with real-time data from remote sensing, either remote imagery, ground sensors or weather sensors. This allows an irrigation system to automatically apply more or less water depending upon the moisture levels at specific field areas.

The most common variable rate irrigation used is in center pivot irrigation. However, variable rate irrigation technology is also available in other types of irrigation, including micro-sprinkler and drip irrigation systems.

All VRT Systems Depend Upon Farm Management Software

Accurate data is crucial to successfully utilizing variable rate technology.

With incorrect or missing data, the VRA will not work at optimum levels and may even be harmful to crop production, applying more water where it isn’t needed or too much fertilizer, for instance.

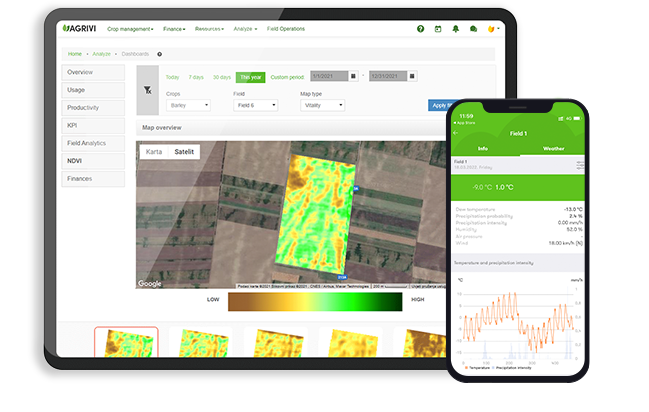

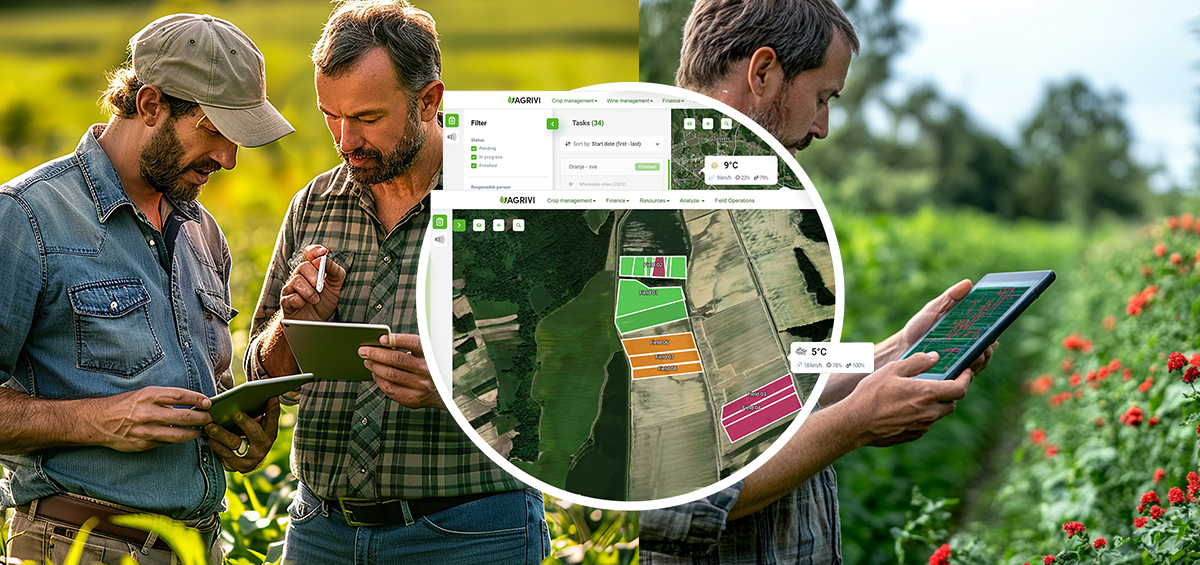

For that reason, VRT and farm management systems (FMS) like AGRIVI go hand-in-hand. AGRIVI’s farm management software collects, processes and analyzes the data a VRT system needs to work most profitably.

FAQ Section

Does Variable Rate Technology Warrant the Cost?

Since the advent of VRT, growers have questioned whether the technology is worth the investment. Agronomists and crop advisers generally recommend that it depends on the variability within your fields and crop production.

For instance, if you farm land that is generally uniform regarding soil types, moisture holding capabilities and terrain, varying seed rates, fertilizers or other crop inputs may not have a noticeable impact. Many farmers, however, do have significant variability within their fields.

In addition, VRT becomes much easier to implement and more accurate — thereby producing better results and more profit — when combined with a comprehensive FMS system like AGRIVI.

How Does Variable Rate Improve the Environmental Impact of Farming?

VRT improves agriculture’s environmental impact in many ways.

Using VRT reduces the harmful chemical herbicides and nitrogen fertilizers farmers use to only the bare amount needed. This means fewer excess chemicals or toxic greenhouse gases are released into the ecosystems and atmosphere from crop production activities.

VRT also maximizes the yield potential of farmland, reducing the pressure to convert native forests and prairie lands into agricultural production. And VRT can reduce the number of passes in the field, reducing the amount of carbon released into the atmosphere by fossil-fuel-burning tractors and farm equipment.

AGRIVI’s VRA Feature for Precise and Efficient Input Application

VRA feature of AGRIVI Farm Management Software enables farmers to optimize their input usage and maximize yields by applying the right amount of inputs (such as fertilizers and pesticides) at the right time and in the right place, based on the specific needs of each crop and soil zone.

AGRIVI uses advanced algorithms to generate prescription maps that guide the equipment in the field. This results in more efficient and effective use of inputs, lower costs, and reduced environmental impact.

With homogeneous rate application, producers could be applying more inputs than necessary on certain locations whilst spending more money and not boosting their yields. Having that in mind there is also the issue of environmental sustainability.

Read more here: Revolutionize Your Farming Operations with AGRIVI’s VRA Feature