AVOID PRODUCT RECALLS

Find out more about avoiding product recalls by downloading your copy of our free ebook.

Did you know that the average recall cost of a product in the food industry can easily amount to as much as $10 million? That number only refers to direct costs. Factoring in the overall cost of crisis management or brand damage can increase that number even higher. In 2019, Tyson Inc. faced exactly that problem. The company had to withdraw nearly 12 million pounds of frozen, ready-to-eat chicken strips which contributed to a $220 million cut to their projected earnings for 2019.

Table of Contents

Why Do Product Recalls Happen in the First Place

Over the years there have been plenty of opportunities that highlight the cost of a product recall. Recalls usually occur when a product fails on quality testing or sanitation issues usually following a food safety and inspection services check. For example, a product recall in agriculture can happen in case of some unallowed active substances or pesticides residue is detected. Essentially, the best way to avoid a product recall disaster is to address the problem head-on with production traceability.

Controlling Business Risks Through Production Traceability

Production traceability can be a turning point in controlling business risks and reducing losses due to possible product recalls, especially in the food industry. Having a complete insight into all food production practices enables food manufacturers to isolate some products from the source of the problem.

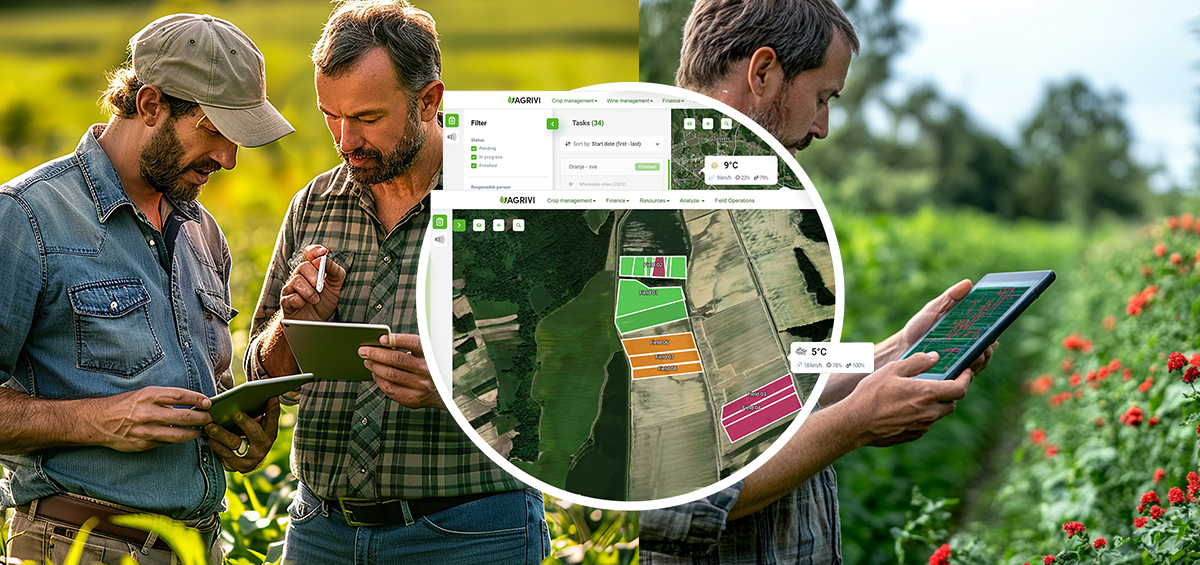

Let’s look at the example of one processing company that collaborates with a network of farmers to purchase fruits for juice production. The company needs to ensure that they get the agreed quantity of oranges by the specific date and predefined price from their farmers. At the same time, farmers are under obligation to deliver a sufficient quantity of crops while respecting the delivery deadline. Additionally, farmers also need to respect the set of quality and food safety standards.

That means that they need to respect strong regulations regarding the applied active substances and avoid any potential residues of pesticides during harvest. Responsible food sourcing standards also restrict farmers to reactive instead of preventative spraying – meaning farmers need to actively monitor their crops and fields and only spray if there is evidence or a significant risk of pest infestation.

All of the aforementioned activities require diligent and frequent record-keeping, collaboration between farmers and their respective distributors, accurate reporting on levels of pesticide residue, and dates of measurements taken. The best way to do that is to keep this data centralized through farm management software like AGRIVI.

Watch the video and discover about AGRIVI agriculture supply chain management software:

Together with regular monitoring of input usage, food companies can ensure compliance with food safety standards by providing evidence that the harvest occurred after the waiting period of a specific pesticide has expired.

What is even more important, providing complete production traceability not only reduces food recalls but also provides added value to the products and ensures an even better position on the market.

Farm Management Software as a Solution to Product Traceability

By digitalizing their farm production, food companies can seamlessly control their supply chain and avoid potential losses due to food product recalls. By following five simple steps farmers and their respective processing companies can use farm management software like AGRIVI to minimize product recall.

Step 1. Pest risk identification

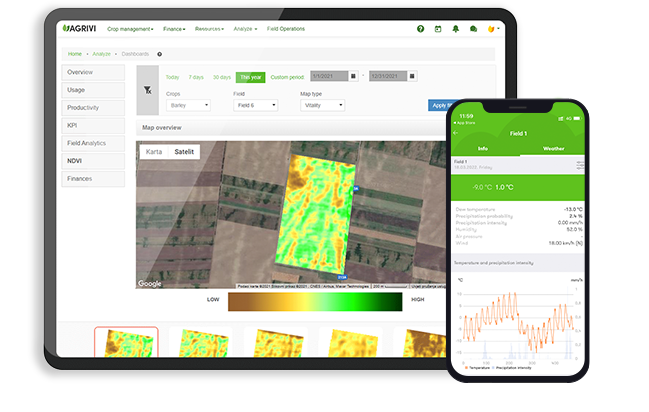

AGRIVI identifies possible pest and disease risks for each crop and field in real-time through smart pest alarms and satellite imagery. The software also reveals problematic areas in any field and can be used to remotely detect scouting locations so farmers can decide whether they need to spray or not.

Step 2. Field inspection and evidence collection

Once farmers perform a field inspection, AGRIVI will support them in registering their pest or disease observation and assist in taking and recording photo evidence. As a result, the company will know that farmers applied reactive instead of preventative spraying.

Step 3. Choosing the right product for crop protection

When farmers do decide to spray, AGRIVI farm management platform provides them with the recommendation of crop protection products that have a valid registration in their countries and which they are authorized to use. In some countries, the list of allowed protection products and their expiration date change every few months. AGRIVI keeps track of that too by scraping online databases of institutions like the U.S. Department of Agriculture, U.S. Food and Drug Administration, or the EU Pesticide Database. So, farmers can always rest assured that the product selection is done right and in compliance with national regulations.

Step 4. Spraying only areas infected, not entire fields

Variable Rate Technology (VRT) comes as a cherry on top to ensure food safety by providing an optimal dose of agrochemicals on each part of the field, rather than spraying the entire field in the same amount or in areas where no spraying is needed. On average, precision application of protection products reduces chemical usage by 20-40%. While improving food safety and sustainability, the precision application of protection products also increases farm profitability.

Step 5. Ensuring traceability for compliance and risk reduction

The best way to achieve consumer product safety and lower the possibility of a recalled product is to ensure complete production traceability, both for compliance purposes and active decision-making.

AGRIVI provides complete production traceability through compliance reporting that allows transparent insight into all farm practices and applied inputs. Traceability-based dashboards support decision-making for critical activities such as determining the harvesting period in which crops are safe for harvest and will not contain any pesticide residues.

Read more about AGRIVI Traceability solution:

- AGRIVI’s Advanced Traceability Dashboard Enhances Food Safety and Transparency for Farmers and Consumers Alike

- How to Gain Consumers Trust? 4 Key Reasons Why Traceability Matters

Don’t let product recalls affect your business and brand position, contact us for a demo and let us help you achieve sustainable agriculture supply management.