Fodder crops are plants grown for green animal feed, hay, or silage, such as alfalfa, field pea, clovers, and various grasses. Along with pastures, fodder crops are in that forages group. Although pastures and fodder crops both belong to the same group, there is a difference that lies in the last stage of their farm management.

While pastures are left for livestock grazing, the main role in harvesting fodder crops is left to farmers. Moreover, fodder crops require additional post- harvest management, as well as appropriate harvest machinery. The direction of fodder crop harvest management, as well as the choice of harvest machinery, primarily depends on the production purpose, whether it’s for growning green animal feed, hay, or silage.

Types of Fodder Crop Harvest Machinery

Initially, the categorization of fodder crop harvest machinery is complex. The main reason for this is because different production purposes (green animal feed, hay, silage) require different harvest management, and therefore, different farm machinery. In this regard, fodder harvesters are used in one of two ways:

- For cutting (mowing)

- For picking up mown crops from windrows (in the case of hay production that requires the previous drying).

Generally, fodder harvesters may be self-propelled, tractor mounted, or pull-behind.

Furthermore, fodder harvesters include different attachments for gathering the crop. These include:

- Direct cut header; used for cutting standing crops such as alfalfa; consists of a cutter bar

- Windrow pick up header; used for picking fodder crops arranged into windrows

- Row fodder header; used for harvesting row crops such as maize

- Snapper headers; used to harvest only the ears of corn from the stalk

Types of Machinery For Different Fodder Crop Practices

Regardless of the production purpose, each fodder harvest theoretically begins with cutting, i.e. mowing. For this, farmers may use simple cutter bar mowers or rotary mowers. Cutter bar mowers use reciprocating knives, while rotary mowers use rotating discs or drums to cut the plant.

Additionally, farmers who produce hay prefer using mowing-conditioning systems that enable faster drying by crumpling and crushing the plant stems.

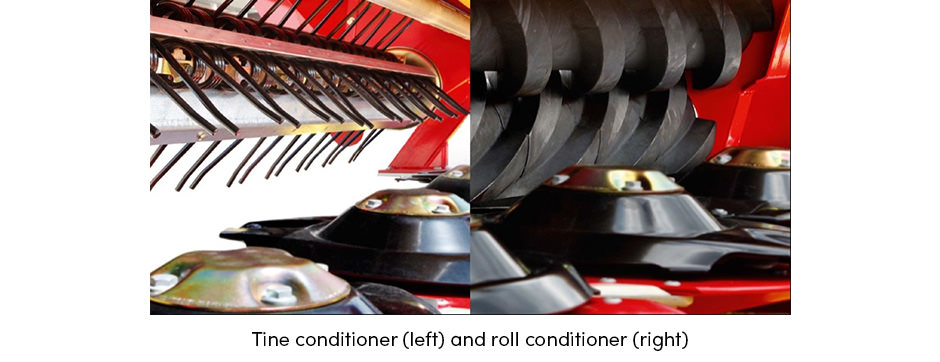

There are two main types of conditioners:

- Roll conditioner; consists of two steel or rubber rolls that crimp and crush the stems with pressure

- Tine, or flail (impeller) conditioner; consists of tines that scrape the stem of grasses, thus removing the waxy surface from the stem and allowing for faster drying.

Drying is an essential component of hay production. Along with conditioners, farmers use tedding machines or inverters, as well as hay rakes. There are several types of tedders and rakes. In fact, the machines for both operations are practically the same. The typical tedding and raking machine consists of several rotating wheels and horizontal bars, with teeth mounted on a spinning reel. However, the difference between tedders and hay rakes is their operational mode.

Tedding machines, (also called inverters), are farming implements used for the spreading and turning over of hay in the field. Tedders expose the underside of- the hay to the sun, thus promoting faster drying. Raking machines gather and turn the partially dry hay into a windrow, allowing the hay to completely dry and the baler to efficiently pick up the hay.

Baling and Wrapping Machines

Balers are machines that pick up the crop in the field and compress it into a bale. Baling is a process common to both hay and silage production. In both types of production the machinery is generally the same. However, some producers offer special silage balers that are designed to manage high-moisture crops more easily.

Balers may be classified into three groups:

1. Small rectangular balers; produce small, lightweight square bales; more appropriate for small-scale farmers

2. Large rectangular balers; produce highly compacted and heavy bales

3. Large round balers; produceround bales and is the most popular baler type; farmers use one of three types of round balers:

- Variable-chamber baler; consists of a number of belts; the size of bales varies depending on the amount of hay

- Fixed-chamber baler; consists of steel rollers or belts; the chamber retains the same dimension from the beginning of hay formation so the final size of the bale can not be changed

- Semi- variable fixed chamber baler; operational principle is the same as in fixed-chamber balers, but the size of bales may vary.

Wrapping machines are used to wrap bales of hay or silage. They come in a variety of shapes and sizes. However, regardless of the type, the common purpose is to preserve the quality and protect the bales from external factors. Farmers may use single wrapping machines or balers that already have wrapping chamber included.

All things considered, the fodder harvest machinery market has a lot to offer, particularly today when the Ag tech revolution continues to offer new possibilities. With modern fodder harvesters that offer real-time mapping of yield and moisture, as well as steer guidance systems, farmers can experience a completely new level of agriculture- precision farming.

So consider all types of fodder harvesters and make sure to choose the one that suits your needs best.