Globally, more irrigated cropland is in demand, driven by rising temperatures and intensified droughts caused by climate change. That demand, combined with new technological advances that make central pivot systems more water and energy-efficient, adaptable, affordable, and easy to use, is driving adoption. And while center pivot irrigation systems are more commonly associated with large-scale farmers, the technology is even finding purchase amongst smallholder farms in African nations through cooperative shared systems.

But while the U.S. is the largest user of center pivot irrigation systems, the technology is spreading across the planet.

Table of Contents

What is a Center Pivot Irrigation System?

A center-pivot irrigation system is a mechanized, pressurized water irrigation method.

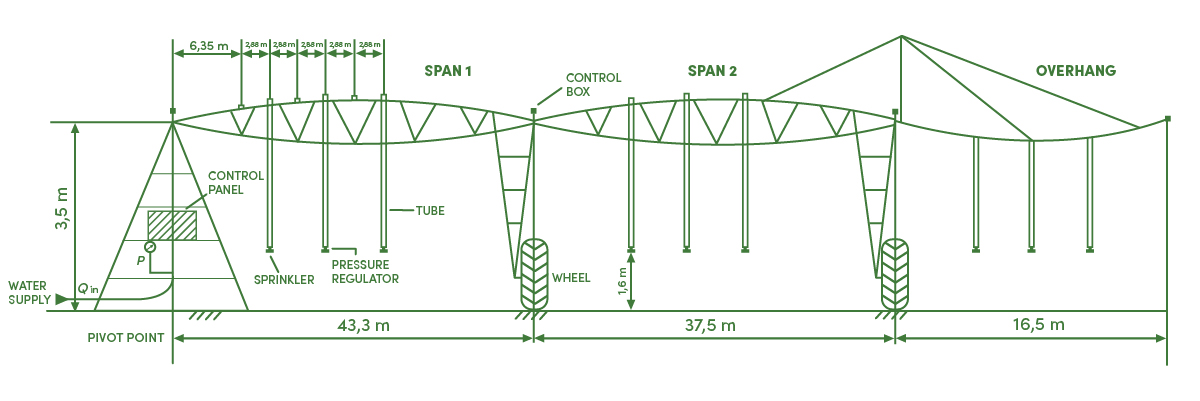

The original and most used style of pivot irrigation applies water in a circular pattern, pivoting around a central point in the middle of the field. A pivot system consists of a lateral, stainless steel pipeline mounted across adjacent, mobile truss structures that support the pipe. Each truss is mounted on motorized wheels, allowing the entire length of pipe to move through the field.

Sprinkler nozzles are installed along the pipeline or hang down from the lateral pipe on smaller pipes or cables. Flow rates and gallons per minute (GPM) can easily be adjusted in a center pivot system and pressure regulators can be utilized to create either a high-flow or low-flow system depending on water use needs.

Since the introduction of center pivot irrigation more than 70 years ago, the unique circle pattern of a field irrigated with a pivot system has become emblematic of America’s highly productive agricultural breadbasket.

Center-pivot irrigation system from seen from the air.

Nebraska, the number three ranked U.S. state for agricultural receipts, is the largest irrigator in the U.S. and boasts the most center pivot irrigation systems. An estimated 55,000 center pivot systems irrigate about 6.7 million acres in Nebraska.

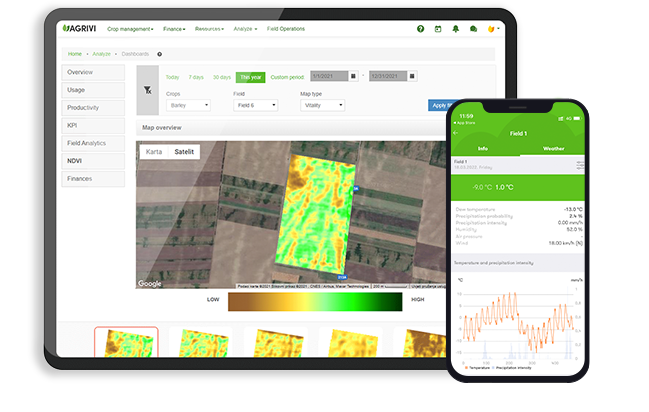

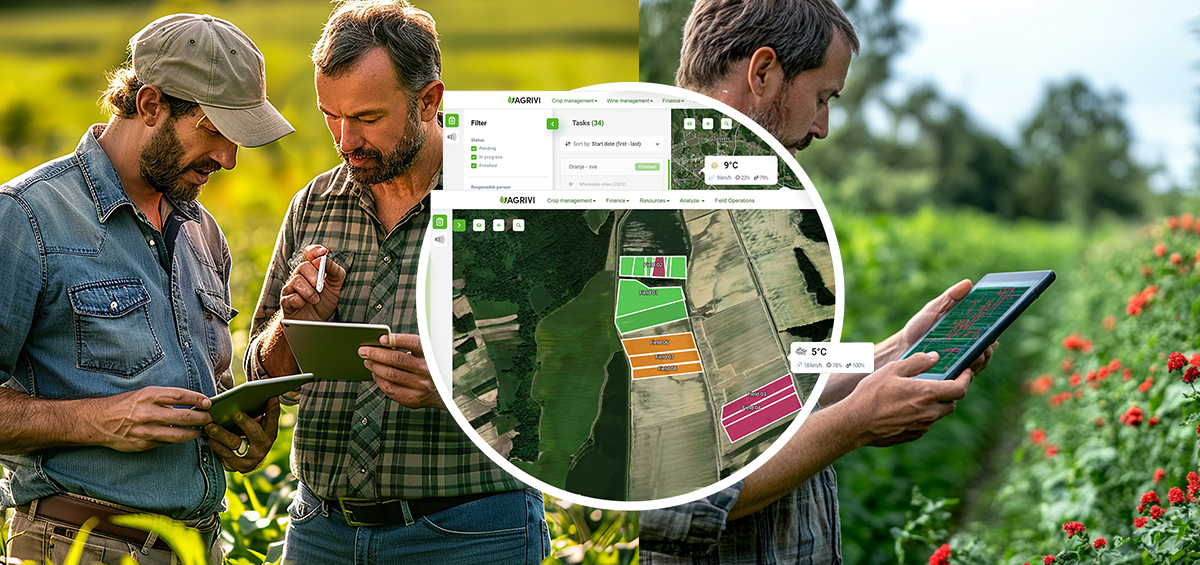

Meanwhile, the growing use of farm management software allows farmers to monitor and capture their irrigation records, including analytics like use frequency, costs and ROI results. Farm management software like AGRIVI helps farmers better manage the sustainability of any type of irrigation system and assess the economic trade-off between installing a center pivot versus other irrigation systems such as flood irrigation, sprinklers or drip and micro-irrigation.

Although they were initially run off water, today’s center pivot systems are typically powered by electricity from a public source or a generator. Motors are installed at the top of each tower. They also may run off a hydraulic engine. Water is delivered to the pivot point from either a ditch or pipes. The water source is typically a well pumping up groundwater from an aquifer system.

Center pivots are adaptable to different terrains and can be used in fields with up to a 30% slope, although 15% is recommended. They can even be used across rolling terrain, making center pivot systems accessible for many agricultural regions. This also means farmers don’t have to move dirt, do field leveling or build the levee and dikes needed for flood irrigation systems.

History of Center Pivot Irrigation Systems

Center pivot irrigation systems developed hand-in-hand with advances in motorized and then electrified wells pumping water out of what seemed to be vast aquifer resources. The many Nebraskan center pivot systems irrigate with water pulled from the Ogallala Aquifer, an extensive aquifer system that runs underneath parts of Colorado, Kansas, Nebraska, Oklahoma, South Dakota, Texas and Wyoming.

Before motorized well pumps, water was drawn out of shallow wells pumped by hand or run by windmills. Motorized pumps allowed wells to be dug deeper and much more water to be pumped out at greater and faster volumes. Rapid expansion of motorized pumped groundwater wells happened around 1945, especially in areas located over aquifers with appropriate agricultural soils.

Diagram of a center pivot irrigation system.

In 1948, Nebraskan farmer Frank Zybach invented the first center-pivot irrigation system after watching farmers laboriously move ground irrigation pipes feeding sprinkler heads across farm fields. Originally called the “Zybach Self-Propelled Sprinkling Apparatus,” Zybach applied for a patent in 1949. The pivot systems quickly rose in popularity.

Today, about 29% of all irrigated land in the U.S. is irrigated using center pivot technology, according to the USDA. Between just 1986 and 1996, U.S. center pivot irrigation land increased by more than 50%.

The Dust Bowl and Center Pivot Irrigation Systems

The Dust Bowl years of the 1930s left farmers in Colorado, Kansas, Texas and the Oklahoma panhandle reeling from the prolonged effects of extended drought and primed for new technology that would prevent it from happening again.

Before the rise of center pivot irrigation, farmers in the Great Plains region dry-land farmed. They relied upon natural rainfall to provide enough moisture for their crop production. In 1930 a severe, 10-year drought began, leaving behind parched farmland that famously blew away in great dust storms.

The Dust Bowl lasted a decade and had a profound economic impact, devastating rural midwestern communities and making useless approximately 35 million acres of former farmland. Though regular rainfall returned in 1939, farmers didn’t forget the Dust Bowl years. So by the time Zybach invented the center pivot irrigation system, Midwest farmers were primed to adopt a strategy that essentially guaranteed they could mitigate the effects of drought.

Before the rise of center pivot irrigation, farmers in the Great Plains relied on natural rainfall to provide enough moisture for their crop production.

Center Pivot Irrigation System Adaptions and Improvements

There are numerous improvements and adaptions to the traditional center pivot design that growers may want to consider with their center pivot irrigation system.

Lateral Move Irrigation System

A lateral move irrigation machine is similar to a traditional center pivot system. However, a lateral move machine moves in a straight parallel line rather than a pivot, allowing for better coverage in a square or rectangular-shaped field. However, because the entire machine moves, the water is supplied from a supply ditch parallel to the field. Lateral move irrigation systems are also more labor-intensive through the growing season than traditional center pivot systems.

Corner Systems

Corner systems are added to a center pivot system to increase the irrigated acreage in the corners of fields and other non-symmetrical regions that the traditional pivot circle misses. A corner system, also called corner catchers or swing spans, is an additional tower and pipe typically installed on the last tower of a pivot span. Using a guidance system which directs the tower where to go, the corner system follows behind the main pivot span.

End Guns

End gun systems are a lower-cost alternative to a corner system. An end gun is a large sprinkler installed at the end of a pivot. They can deliver irrigation water up to 120 feet out from the outer end of the pivot machine. However, end guns do not deliver water as uniformly as the regular pivot, potentially causing problems of under or over-irrigated sections of the crop.

Towable Systems

A towable center pivot system is a pivot system installed on a towable end tower. Farmers can hitch their tractor to the end tower and move the pivot between fields. Towable systems are helpful for smaller areas or where growers are using their pivot to provide supplemental irrigation to average rainfall. However, because they require labor to tow them around, they may not be practical in arid areas requiring intensive irrigation.

LEPA System

LEPA stands for Low Energy Precision Application. LEPA is used in both center pivot and linear move systems. In a LEPA system, sprinkler nozzles are mounted close to the ground and water application is emitted at low pressures. This reduces the amount of water used and saves energy. LEPA systems are helpful in high-wind areas prone to evaporation. However, LEPA systems contribute more runoff, and because the water application may be below the crop canopy, a LEPA system may damage the crop.

The Pros of Center Pivot Irrigation Systems

Economical for Larger Operations

Because center pivot systems operate autonomously, requiring very little labor once set up and are typically long-lasting-a system usually lasts around 20 years with just routine annual maintenance-they are a good investment for larger farm operations.

Highly Water Efficient

In ideal conditions, a well-designed center pivot system can have a water efficiency rate of 85 to 95%, making them more efficient than sprinkler irrigation and flood irrigation systems.

Useful for Pesticide and Fertilizer Applications

Center pivot systems are easily adapted to chemigation or fertigation, giving farmers a cost-effective and uniform way to apply crop inputs such as fertilizer or pesticides.

The Cons of Center Pivot Irrigation Systems

Initial Outlay is Expensive

The initial cost of a pivot system can be substantial, running close to $80,000 for a standard 160-acre system, including power and water source. Fuel and electrical costs are also a consideration in pivot operation.

Inefficient for Square or Rectangular Fields

Without swing arms or corner systems, water distribution in pivot irrigation systems does not reach the corners of fields.

May Encourage Plant Disease

The frequent irrigation schedule of a pivot system creates moist and humid conditions, which may encourage fungal diseases, especially near the tower closest to the pivot base.

Next-Gen Technology for Center Pivot Irrigation Systems

Like all irrigation systems, next-gen technology and precision agriculture methods provide new strategies for making center pivot irrigation systems more sustainable and cost-efficient.

Variable Rate Irrigation for Center Pivot Systems

Variable-rate irrigation technology allows farmers to vary the amount of irrigation water applied to match soil conditions and plant needs. Variable-rate technology works in conjunction with satellite or drone imagery, soil moisture sensors or weather data stations, and GPS technology, telling the pivot at what point and in what quantities to irrigate.

Farmers may use variable speed, changing how quickly a pivot moves through a field and staying in sections that need more water for more extended periods. Or, they might use a variable zone irrigation technique, varying the application rate along the width of the pivot lateral.

Farm Management Software and Irrigation Management

The AGRIVI farm management system helps farmers analyze results, monitor costs and effectively make irrigation decisions, no matter what type of irrigation system or irrigation equipment is used.

Farmers can easily record and track irrigation-related activities, such as the frequency and duration of irrigation events, water used and source, and analyze costs. Then, at the end of the season, farmers can use AGRIVI analytics to assess their irrigation decisions and implement changes based on the best ROI for crop needs and farm economics.

AGRIVI also extends its water management capabilities by enabling farmers to manage and automate water distribution across their fields using our Internet of Things (IoT) hardware together with the new Fertigation Management System. In scenarios where water resources are limited, this technology becomes invaluable. By ensuring that water is delivered precisely where and when it’s needed, farmers optimize their resource allocation, conserve water, and save valuable time and labor.

Ready for better and more sustainable management of your center pivot irrigation system? Or do you need help assessing whether a center pivot irrigation system would be the right choice for your farm? AGRIVI and our farm-specific experts can help you find the best solution for your needs.

Download our free eBook and discover how to buy Farm Management Software in 6 steps.

Center Pivot Irrigation FAQs

What Crops Can Be Watered with a Center Pivot Irrigation System?

Almost all crops are appropriate for pivot irrigation systems, including corn, soybeans, small grains, alfalfa, potatoes and vegetable crops. Orchards and vines are also adaptable to center pivot systems.

Are Center Pivot Irrigation Systems Sustainable?

Center pivot irrigation systems are among the most water-efficient ways to irrigate crops, with anywhere from 85 to 98% water use efficiency. This is a much more sustainable water use than irrigation systems such as surface irrigation, also known as flood irrigation. However, the explosion in center pivot irrigation systems using groundwater pumped from aquifer systems has been blamed for causing critical aquifer depletion in many prime agricultural regions.

Are Center Pivot Systems Energy-Efficient?

Even though center pivot systems require a power source to operate because they are flexible and designed to deliver water efficiently over a large area, they are more energy-efficient than many other irrigation systems, especially sprinkler systems.

Is Evaporation a Problem in Center Pivot Irrigation Systems?

Evaporation is observed in center pivot irrigation systems in high-wind conditions. Spray heads mounted on the top of the pipe may experience evaporation and wind drift losses up to 15%. Appropriate system design can significantly reduce evaporation.

What is a Center Pivot Control Panel?

A control panel is hardware attached to the pivot point that gives commands to the pivot machine. Controls are things like starting, stopping, and changing direction.

What is a Center Pivot Span?

A span in a center pivot system is the long pipe between drive units (trusses) that support the span. Water runs along the span and sprinklers are attached to it.